The fundamental approach is straight-forward design for power torque and speed then shaft loads and finally mixer dynamics. Two minute mix The minimum dry mix time is 25 of two minutes or 30 seconds.

The Paint Machineries Were Using For Paints Diposing Purpose It Offer The High Speed Disperser It Is In Differet Different Si Machinery Manufacturing Sealant

This gives operators a higher level of control over the material moving through the mixer.

. Water specific weight γ 0. 1000 s-1 t 30 s. CV Calculation CV sm 100 m Σ X in s2 Σx i 2-nm n S s2.

Low Pressure Drop Static Mixers for Turbulent Flow Processes. Concrete is an important component required for construction of houses and roads. We also have a handy calculator down below just plug in your information and well do.

- R is the radius of the mixing tool center of shaft to tip of paddle in m. Batch mixers similar to food mixers are a primary method for the processing of many materials. These are made available to help you do preliminary mixer sizing mixtank volume calculations some mixer mechanical design calcs etc.

R is the radius of the mixing tool center of shaft to tip of paddle in m n is the mixing speed in rpm. Small-scale motions are not available and mixing is a result of large-scale motion in the flow. Radial Flow high shear mixing industry standard design diameters 3 to 24 standard mill stock Np 0325 baffled Nq026 Cowles Disperser - Multi-Blade STX Parabolic PS2 Back.

The minimum wet mix time is 75 of two minutes or 90 seconds. Paddle mixer of forced action for. Mixing Equipment Design Mixing and Mixer Problems Uniformity Testing Animal Performance.

One minute mix The minimum dry mix time is 25 of one minute or 15 seconds. Power dissipated P 0. The sound design of a double-shaft mixer with a horizontal shaft and rectangular buildings are given in the article on the basis of a priori review.

Design consideration of this paper is to calculate Mixing Force Mixing Value belt tension and required power by mixer. Static Mixers are well known for their wide ranging uses in turbulent and laminar flow mixing applications. In general the higher the capacity the wider the trough will be.

The mixer should be the bottleneck of the installation of mixing which means that it should not be slowed down by the process section upstream or downstream. Pugmill mixers can be designed to process material from 500 lbhr all the way up to 250 TPH. The experimental feed mixer is designed and.

While WMP is determined to provide accurate information no expressed or implied warranty is given by WMP as to the accuracy and usefulness of this information. The ribbon tip speed can be calculated thanks to the following formula. Inconsistent mixture quality residual voids and fissures limited pot life etc.

The result obtained show the Mixing force of 14715 N mixing volume of 0348 m 3 and required power by mixture of 243 hp. White Mountain Process LLC WMP provides this calculator for reference only. By using this mixing formula you will see why the ASC Tornado is the most effective and efficient mixer on the market.

Paddle Wheels Design The power imparted by paddle wheels is given by the following. For larger systems above 100 hp it may be prudent to perform a mixervessel system modal analysis finite. For smaller jobs the concrete made at the.

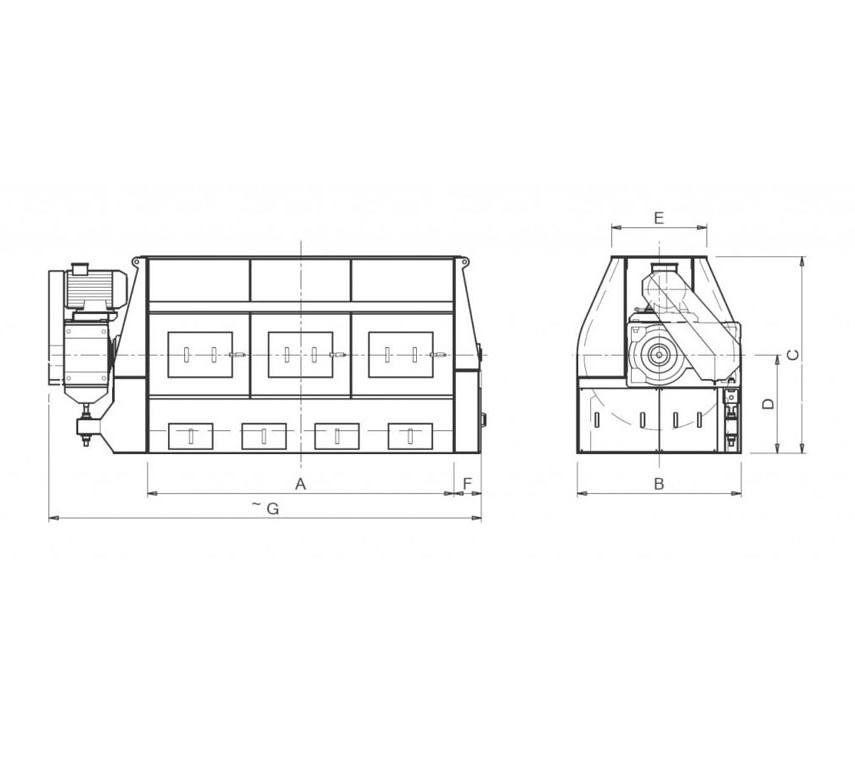

Abstract- In this paper describe the design and calculation of concrete mixer for weight 350 kg approximately. Those designs should not be confused with double shaft paddle mixers or shear mixers ploughshare mixers. Horizontal Paddle Good tumblingpoor side-to-side action.

Best option w fibrous. - n is the mixing speed in rpm. MIXER DESIGN and.

Power of 3 HP. 2 2 3 v3 g C A v P CDA D γ. However there are inherent drawbacks to a batch mixing process eg.

Single shaft ribbon mixer. As a general rule of thumb we follow the formula described below for calculating the mixing rate in gallons per minute of material moved through our patented mixer blade. The power P consumed by an impeller is related to the volumetric circulation rate Q pumping capacity and the velocity Head Delta H from the impeller by.

The pumping capacity of an impeller is defined as the volumetric flow rate normal to the impeller discharge area. Theoretical calculations and machine limitations are used to help determine the balance between. The mixer figure 1 for bulk materials mixing consists of a cylindrical drum 1 installed in the support element 10 which is fixed to the base 12.

Many pugmill mixers are designed to accommodate various paddle arrangements. The second step in the design sequence is the mechanical design of the mixer components. Paddle arrangement plays a key role in mixer retention residence time or the time required for the material to be in the mixer to produce the desired results.

CD Coefficient of drag A Paddle area ft2 m2 ρ density of the liquid ρ γg v Velocity of the paddle relative to water fps mps g gravity 3217 ftsec2 981 ms2 Table 83 gives values for drag coefficient. Each design can be supplied as complete plug-in modules or as removable elements for installation into the end users preferred housing design. The capacity of the installation should b.

White Mountain Process is happy to provide these free mixing calculators for your use. A concrete mixer machine is a device that homogeneously combines cement aggregate such as sand or gravel and water to form concrete. 7 38 x 9 14 Technical Complete Wireless Design Sayre 4452-6 Chapter 7 CHAPTER 7 Mixer Design M ixers are three port active or passive devices are designed to yield both a sum and a difference frequency at a single output port when two distinct input frequencies are inserted into the other two ports.

During loading and discharge the mixer speed must be such that the tip speed of the paddles is 1 ms. This process called frequency. The mixershould be the bottleneck of the installation of mixing which means that it should not be slowed down by the process section upstream or downstream.

Design considerations involve energy input such as G the root mean square rms velocity gradient detention time degree of flocculator compart- mentalization and the type of shearing device such as paddle design. There is a hatch in the lower part of the drum which is used to unload mixes and is closed by the cover 8 with the help of the lever 14. The mixer selection program allows you to calculate flow rates and power draw of mixing impellers see what the agitator will provide.

The Geometry Of The Horizontal Ribbon Mixer With A Double U Shaped Download Scientific Diagram

High Shear Dispersor Stainless Steel Cowles Disc Sawblade Mixer Sawtooth Impeller Buy Dispersing Mixer Dispersing Blade High Speed Di Mixer Saw Blade Steel

Configuration Of The Mixer Showing The External Shell And The Plough Blade Download Scientific Diagram

Agitation Tank Design Calculations Agitation And Mixing Equipment Design Youtube

Mixing Process Engineering Wikiwand

Single Shaft Horizontal Mixer Feed Paddle Mixers Feed Mixer Fragola S P A

Process Schematic Showing Major Inlet Outlet Streams Heating And The Download Scientific Diagram

Pin By Hannah Reu On Tips Mixer Recipes Kitchen Aid Recipes Kitchen Aid Mixer Recipes

0 comments

Post a Comment